lron Ore

it has different types including hematite iron ore and magnetite iron ore, is considered one of the most useful and important minerals produced. Our iron ore is offered to buyers directly from the mines in different types with high quality and reasonable price.

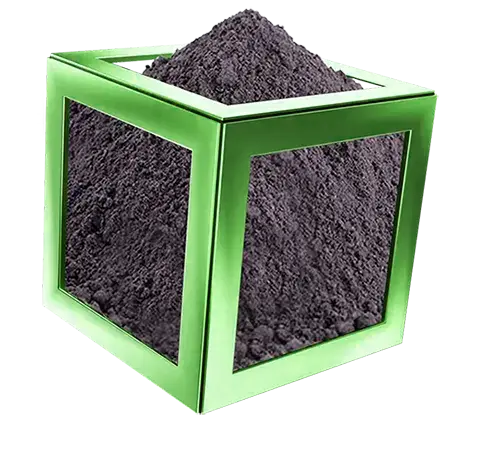

Iron Concentrate

lron ore processing after mining, Phosphorus, sulfur, alumina, silica etc. To remove impurities, it is necessary to increase the purity and grade of iron ore. Concentration is one of the stages of this process and the stage before pellet production. we offer this product directly from the manufacturers to our customers.

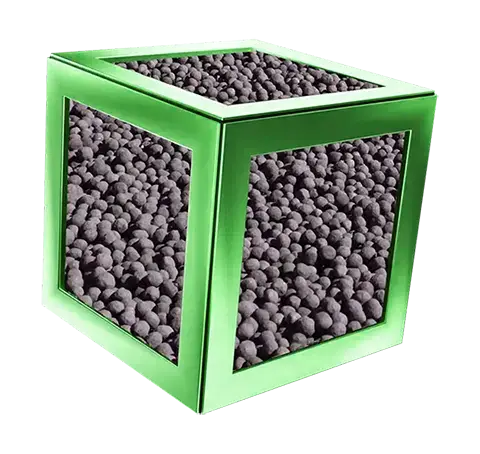

Iron Pellet

The concentrate cannot be physically consumed and therefore soft iron is first turned into raw, then cured and hardened pellets and used for iron production in the blast furnace or for recovery by various methods. We source this product directly from major manufacturers and offer it to our factories and customers.

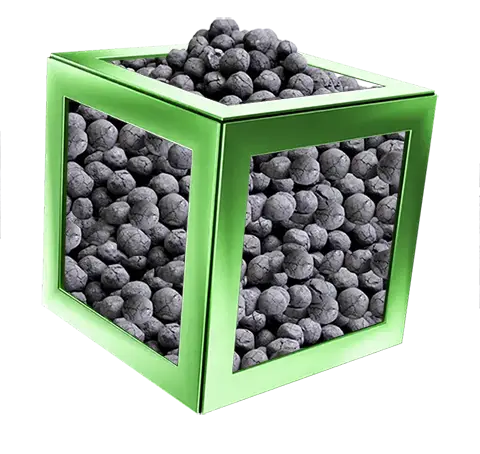

Sponge Iron

Sponge iron is obtained from the direct regeneration of iron ore pellets, and its high quality makes it a suitable source for iron and steel production. This product is a suitable substitute for iron waste. As a result, a high rate of raw material can be obtained by using this material to ensure that the steelmaking units have the necessary melting instead of using waste.

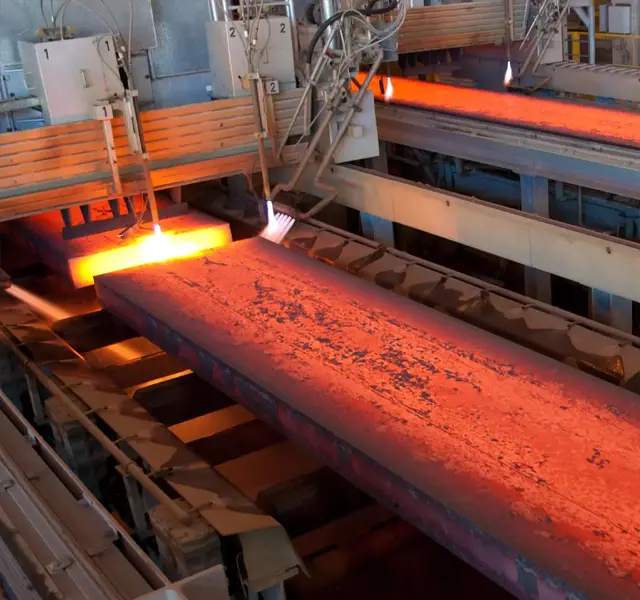

Steel Slab

Steel slab is an intermediate and semi-final steel product obtained from the ingot rolling process or continuous casting process. It has a length ranging from 4 to 12 meters and a rectangular ross section and is used as a raw material for making flat rolled products, including coils and hot rolled sheets. We procure Steel slab from the best manufacturers and make them available to customers.

Steel Billet

Steel billet products in 3SP and 5SP grades with a cross-sectional size of 150x150 are produced with very high quality for the manufacturing of other products. We offer this product to our customers with the highest quality and the most competitive prices.

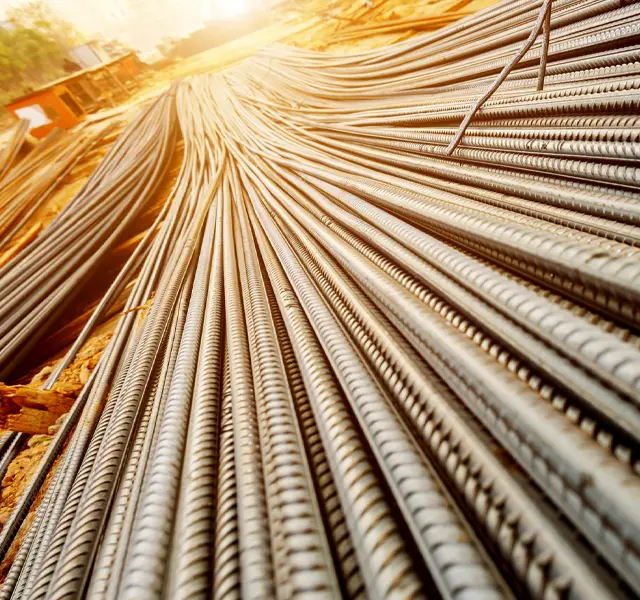

Steel Rebar

Our rebar products are manufactured in various models and sizes using the hot continuous rolling method, with very high quality, in reputable rolling mills across the country.

Steel Coil

Hot rolled sheets are the most famous steel sheets used in various industries such as the construction industry, tanker manufacturing, automobile manufacturing, special tanks shipbuilding, and heavy metal industries, depending on the type. Cold rolled sheets also form the basis of galvanized sheet production. we buy these products from the best manufacturers and make them available to buyers.

Coke

Coke is a refined carbon product used in blast furnaces and one of its main uses in the metallurgical industries. The coke in the blast furnace has different roles such as providing energy, revitalizing iron ores, creating porosity for the passage of invigorating gases and carburizing cast iron.

Ferrosilicon

Ferrosilicon is one of the ferroalloys used in various industries, especially in the metallurgical industries, and is very important in this respect. How this material is used in industry largely depends on the iron and silicon ratio and granularity. we prepare this product from the highest quality sources and deliver it to our customers.

Ferro Silico Manganese

This ferroalloy is actually a combination of ferromanganese and ferrosilicon, and high carbon ferromanganese furnaces are used to make ferrosilico-manganese. Since ferrosilico-manganese offers the properties of both ferromanganese and ferrosilicon ferroalloys, it is used as a substitute for these two ferroalloys in the steel industry. Also, the two elements silicon and manganese form compounds, helping to increase the hardness and strength of the steel.

High Carbon Ferro Manganese

Ferromanganese is obtained from the combination of manganese oxide and iron oxide at high temperature and in the presence of molten carbon in the form of coal or coke. In addition, this process is carried out in electric arc furnaces. Regarding the application of such ferromanganese , it can be mentioned that they are deoxidizing in the production of iron and steel castings, and their use in the manufacture of various welding electrodes, often with a high carbon content.

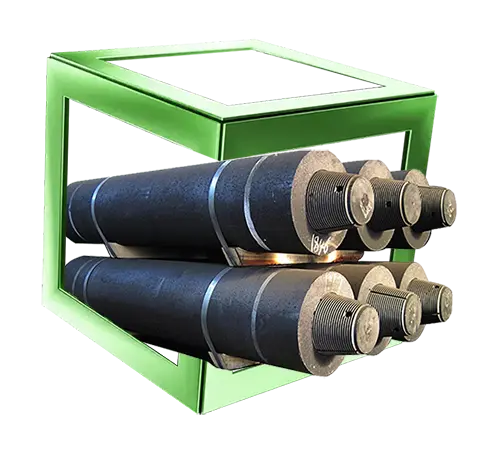

Supplier of Graphite Electrodes

Graphite electrodes have a suitable capacity to create high electrical conductivity and the ability to resist the heat produced and used to create an electric arc, often in steel melting furnaces. Otana company has become a reliable business partner for the country's steel industry in first-class quality graphite electrode products, as well as establishing a business policy based on reliable services, relying on strong business relationships with international manufacturers of this strategic product.